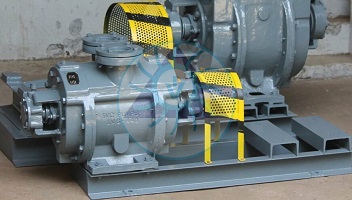

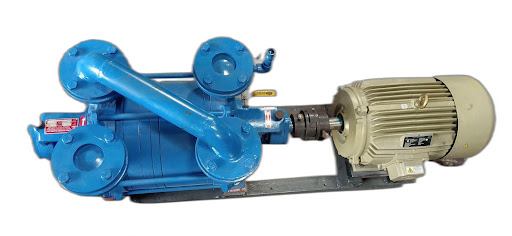

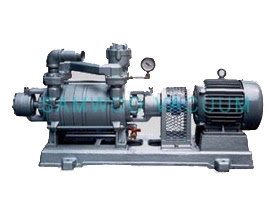

پمپ وکیوم ۳۰۰ مترمکعب آب در گردش مدل FARAS فرس

پمپ وکیوم ۳۰۰ مترمکعب آب در گردش مدل FARAS فرس

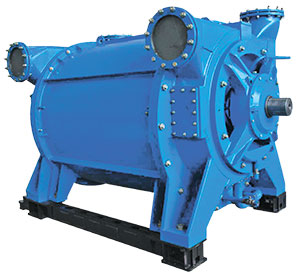

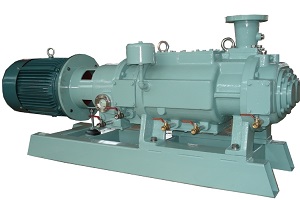

پمپ وکیوم ۳۰۰ مترمکعب آب در گردش مدل FARAS فرس یک دستگاه صنعتی است که برای ایجاد خلاء و انتقال مایعات در صنایع مختلف طراحی شده است. این پمپ به طور خاص برای استفاده در شرایطی که نیاز به خنکسازی با آب وجود دارد، مناسب است.

مشخصات فنی پمپ وکیوم ۳۰۰ مترمکعب آب در گردش مدل FARAS فرس

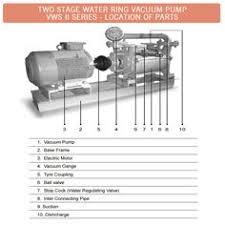

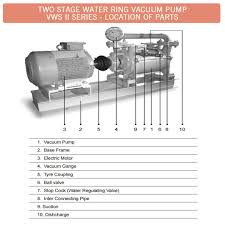

– نوع پمپ: پمپ وکیوم آب در گردش (رینگ آبی)

– توان مکش: ۳۰۰ مترمکعب در ساعت

– موتور: مجهز به الکترو موتورهای ۲.۲ کیلووات

– کاربرد: مناسب برای صنایع سنگین که نیاز به خنکسازی با آب دارند.

ویژگیهای پمپ خلاء ۳۰۰ مترمکعب آب در گردش

– فیلتر نانو: این پمپ دارای فیلتر نانو برای جلوگیری از ورود گرد و غبار به داخل دستگاه است، که عمر مفید آن را افزایش میدهد.

– ساخت کشور: این محصول ساخت ایران بوده و در بازارهای داخلی قابل دسترسی است.

قیمت پمپ خلاء ۳۰۰ مترمکعب آبی

قیمت این پمپ در بازار حدود ۱۱۵,۷۳۶,۰۰۰ تومان میباشد.

این پمپ وکیوم به دلیل کارایی بالا و طراحی مناسب، گزینهای عالی برای استفاده در صنایع مختلف محسوب میشود.